Since some of you have asked me about the different saw and dado blades I use with my new bench table saw, I’ve decided to write this short article clearing this up.

What type of blade is best for a portable bench table saw?

It’s a mobile workbench fitted with a bench table saw and router table. In this picture you can see an orange CMT brand blade which I’m using with the Dewalt dwe7492-QS bench saw.

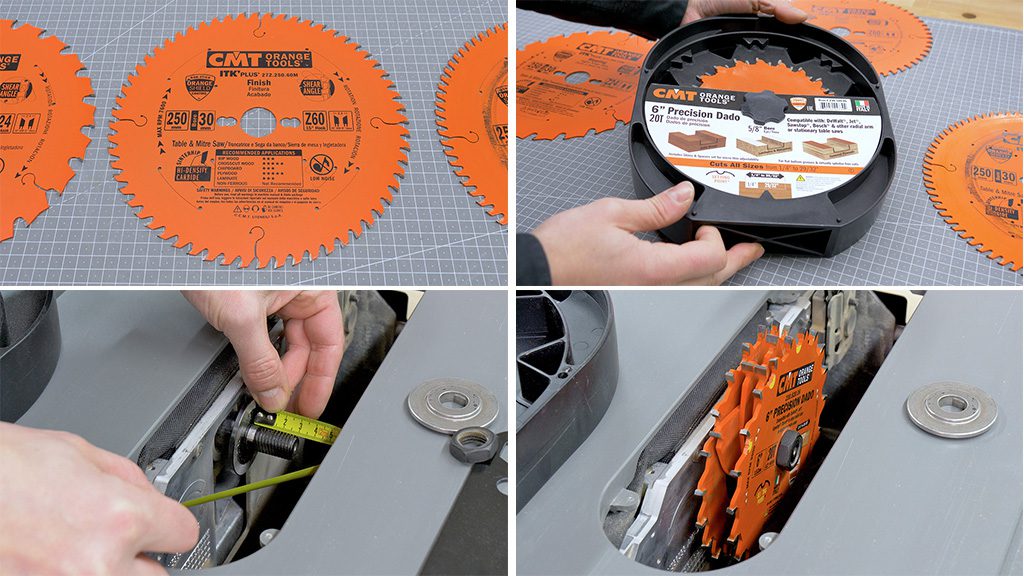

Now I’ll show you the three types of blades I use with my table saw. All three of them are from the same blade series; the only difference between them is the number of teeth. This means they’re all the same thickness, 2.4mm. They all have the same shaft diameter, 30mm. And also the same outer diameter, 250mm. This is the maximum blade diameter that my bench table saw can support, so I’ll take advantage of the full cutting height this saw can offer.

The first one has 24 teeth and is perfect for ripping solid wood boards, but not that great for cross cuts or cutting boards.

The second one has 60 teeth and is a jack of all trades, so to speak. It can do all kinds of cuts in all kinds of materials, but it isn’t as good at each specific job as the other two.

The third saw blade has 80 teeth and is perfect for crosscutting wood and cut all kinds of boards, even ones with melamine. Since it has so many teeth, it’s not the best blade for rip cutting.

Ideally, we should have all three blades, but if you can only buy one, the second one will be the best option. You can make almost all kinds of cuts with it.

Advantages of choosing the right bench table saw blade

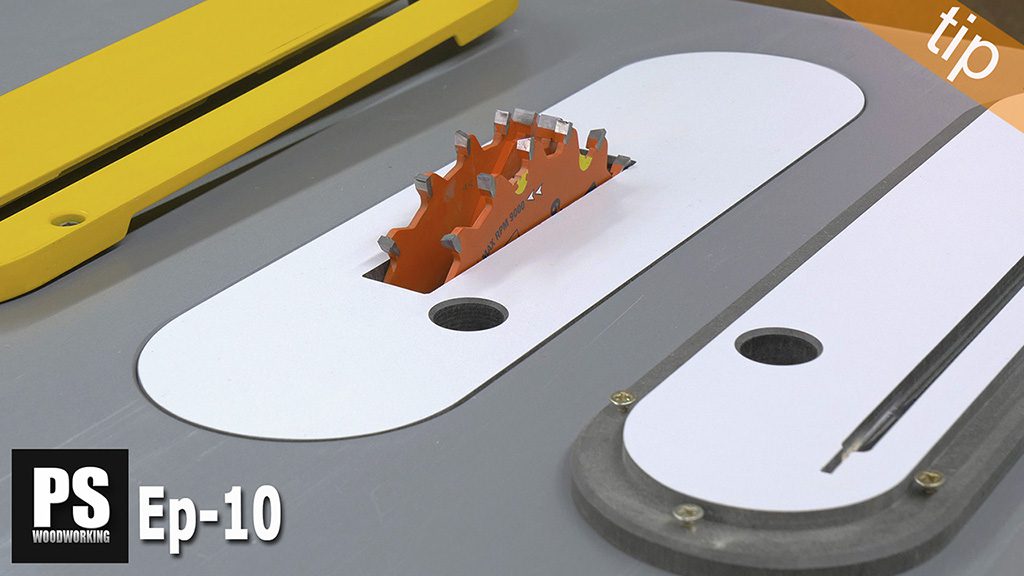

The other advantage of using blades with the same thickness is that I can use the same zero clearance inserts and won’t have to adjust the measuring tape indicator of the sliding carriage of the table saw sled.

These are thin, lightweight blades, which makes them perfect for these kinds of bench table saws because their shaft isn’t as firm as other stationery saws, meaning we won’t push its motor as hard.

If you want to know more about how I made the homemade zero clearance inserts which I’m using with my bench table saw and can be seen in these pictures, you’ll find more information in this article.

How to choose a stack dado blade for your bench table saw

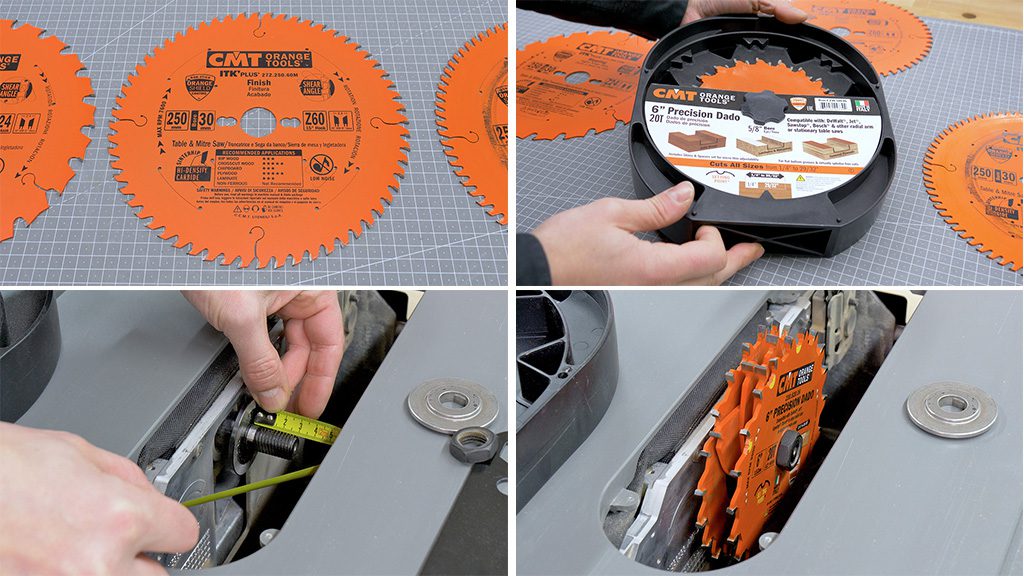

This is the dado blade I use with this bench table saw. It’s about 150mm in diameter and thanks to all its blades and spacers, it can cut grooves between 6 and 23 mm. The central shaft hole is 15.8mm, the usual shaft diameter for this type of table saw.

Thanks to its small diameter, it’s much lighter than other dado blade, and, like earlier, this will allow me to not push the motor and saw shaft so hard. Keep in mind that when we use all the blades and spacers of the dado blade, the motor will have to bear a lot more weight compared to a simple cutting blade.

These kinds of blades are typically used to make shallow grooves, so its reduced diameter won’t be a problem most of the time. With this saw and dado blade, I can cut grooves up to 30mm deep. I think that’s more than enough. In order to use this kind of blade, your saw should have a shaft that’s at least 30mm long.

Are dado blades illegal in Europe?

Many of you have asked me about the European regulations about the use of these kinds of blades, and to be honest, it’s not very clear. What the European regulations say is that dado blades can’t be used with table saws that don’t have an appropriate shaft to accommodate them. I think this is one of the few saws available in Europe with a shaft that’s long enough to use with dado blades.

The problem is the European regulations explicitly forbid making any kinds of cuts with a table saw without the riving knife that’s just behind the blade. To use these dado blades, it is indispensable to remove the riving knife. This is the problem with dado blades in Europe. They’re not technically banned, but they’re virtually impossible to use while complying with all the regulation.

In my case, I’m taking a risk by using it without the riving knife. I guess the worst that can happen is that if I have an accident, insurance policies won’t cover it. I’m trying to come up with a way to use this dado blade and riving knife at the same time, but I doubt it will be an easy task.

As you can see in the first photo, I’ve made a zero clearance insert for use with the dado blade. I can also use the table saw sled for cutting grooves with the blade. In the third picture, I’m making some grooves for the mobile workbench’s drawer spacers. In the fourth picture I’m using the table saw sled and the dado blade to make a tenon.

On this website, I have another interesting article where I demonstrate how to calibrate or adjust the bench table saw’s blades and fence, which you can see in this article.

hello

I will appreciate if you can tell me where did you purchase CMT dado stack?

I cant find it in EU.

Thanks

hi Rozario, everything related to dado blades is complicated in Europe. It seems that at this moment it is not easy to find the same model.

Have you done an online search for this reference? CMT 230.520.06

Hi,

I got the dado stack over Amazon (ordered in Germany, delivered from Italy).

Jan

Curious what your thoughts are on the new CMT “Locked dado” set that is compliant for EU regulations 230.312.08M

hi Greg, I had not seen it, it seems perfect for this type of bench saw!

Hello Greg

I am new to dado blades.

I would like to know if I should choose metric or inch,

I am not talking about the diameter of the shaft which is 30mm on my machine

knowing that I live in France

is there a relationship with the thickness of the boards that we find in France?

thank you in advance

Hello I have the 7492 but European… the bore is 30mm, I see that you use these blades with the same bore as mine, but the Dado is 5/8″ = 15.825 mm how do you do? do you have an adapter.

Thank you for your answer,

Arnaud from France

sorry, I have by looking better at the photo understood the washer left aside and which is not replaced to be able to fix the dado system …

Arnaud