After using my new table saw with a cast iron table and an induction motor along with my Mobile Workbench, I would like to compare it to the other jobsite saw I had been using to show you why I decided to change it.

First of all, I’d like to say that both saws are perfect for DIY and for using with the homemade Mobile Workbench, each in their own category.

Differences between cast iron and aluminum table saws?

Even though there are more than just these two types of table saws, these two are the most used. I think the main variables to take into account when choosing a saw for your workshop are the type of motor, its power, the material of the worktable and its weight.

A jobsite saw with a cast aluminum table weighs around 15-25 kg. A bench table saw with a cast iron table, such as this one, weighs around 90 kg. This huge difference in weight makes the former ideal if you want to take it somewhere, like a construction site.

Differences between and induction motor and a universal brush motor?

This is the motor of the Dewalt 7492 QS jobsite saw (photo above). It has a universal brush motor which rotates at 4800 RPM. This is the 2000W model, so it’s quite a powerful motor.

The Axminster brand table saw with a cast iron table has an induction motor of 1500W and 3000 RPM. Brush motors are lighter, louder and less stable than induction motors. This makes it so that the vibrations of an induction motor aren’t felt as much, making the experience of working on the table very different. Besides the motor, the total weight of the saw with the cast iron table is a plus when it comes to stability when working.

Excessive vibration can also be due to the fact that in jobsite saws, the motor is usually attached to the underside of its aluminum table. In the case of table saws with cast iron tables, the motor is attached to the body of the saw. Even though the saw with the cast iron table is less powerful, I haven’t felt the difference when working. I think the inertia of the rotation of its heavier blade makes up for this small difference in power.

If we look at the manufacturers’ specifications, there isn’t that big of a difference when it comes to how noisy these saws are. The impression I get is that the saw with the cast iron table and induction motor is quieter. The only problem of an induction motor, besides its weight and size, is that it generally doesn’t have an electronic brake to stop the blade’s rotation, which universal brush motors do. Due to this and to the inertia of the rotation, the induction motor saw takes about three times as long to stop. This would be a small plus to the jobsite saw.

Cast iron table saws have bigger and heavier shafts and bearings. They generally also have a more powerful motor, making them able to support thicker blades. Typically, blades are about 3.2mm thick. With other saws, it’s best to use a 2.4mm blade. Thicker blades tend to bend less when working and make better cuts.

The thread lead screw for lifting the blade on the cast iron table is also more robust and operates more smoothly. In jobsite saws, it’s important to make these components lighter. A related point is the time it takes to lift or lower the blade. It’s much quicker on a cast iron table saw, definitely another great advantage.

The way to tilt the blade on the Dewalt saw is using gravity. It’s a very awkward and imprecise system. The Axminster saw has a thread lead screw which allows it to find the desired angle in a more comfortable and accurate way.

How to change a table saw riving knife?

Something that came as a pleasant surprise about the Dewalt saw some time ago was the coupling system of its riving knife. All you have to do is pull a lever and pull the knife, even if the zero clearance is in place. A far cry from the Axminster’s slow and awkward system. In this case, we have to loosen two screws.

The maximum cutting height is similar for both saws, around 80mm. Both saws support blades that are 250mm in diameter. I have also noticed that the paint that covers the aluminum on the worktable has worn off, something that will never happen in a cast iron table.

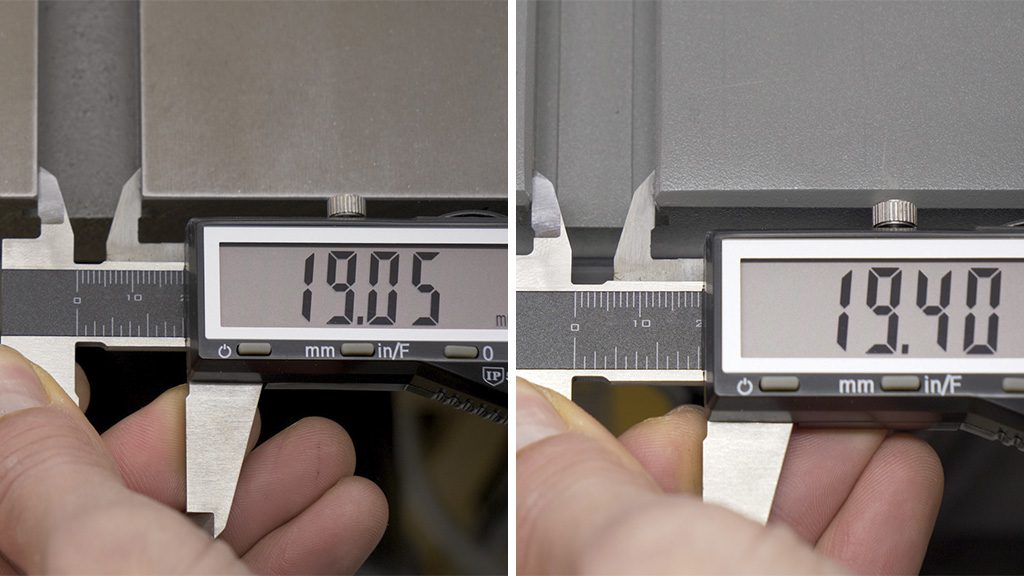

The Axminster saw has standard sized miter slots, 3/4” or 19.05mm. In the Dewalt, the slots are a few tenths of a millimeter bigger than usual, which can cause some problems when using accessories such as the miter gauge.

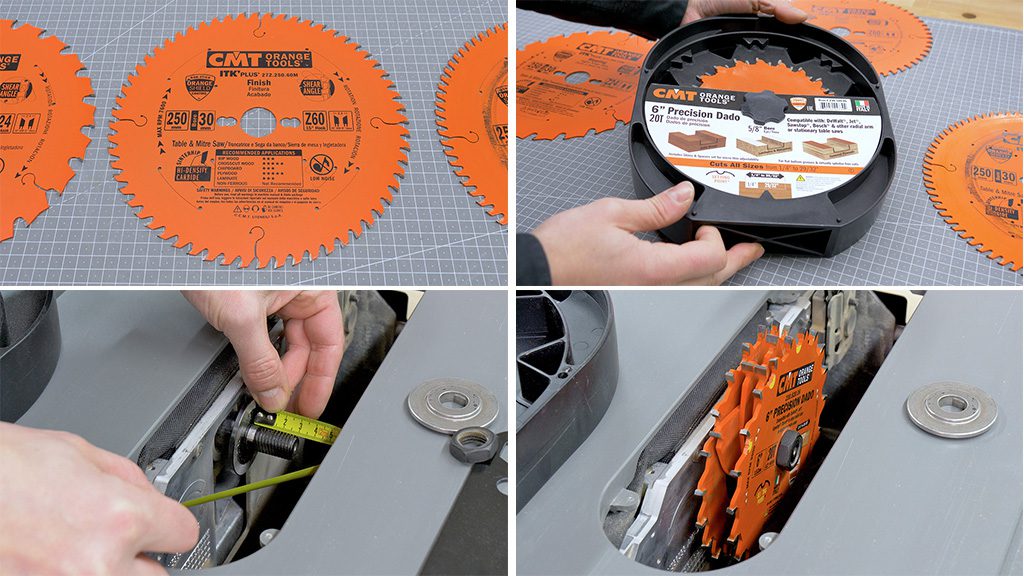

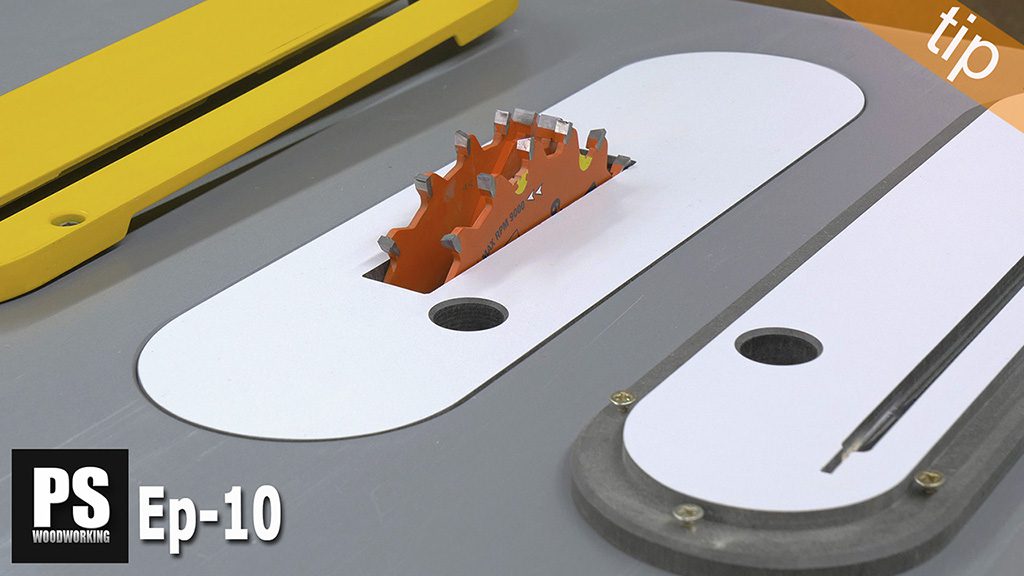

Differences when using dado blades

It’s time to talk about dado blades. The Dewalt saw has a long 30mm shaft which can support dado blades of smaller diameters, making it more versatile. Not many jobsite saws allow you to use dado blades.

Almost all large table saws with a cast iron table can support dado blades of any diameter. In this case, since it’s a small bench saw, the shaft is only 20mm long. I’ve made a small modification in the shaft so that I can use part of the dado set I have in my workshop.

Rip capacity with the fence

The rip fence of the Dewalt saw is two-geared, so there’s barely any slack even in the back part, and it’s always parallel to the blade. The downside is you’ll have to change its position depending on the size of the cuts. It’s also more tedious to remove it from the saw when needed. This was fairly annoying when I was using it with the Mobile Workbench, but it won’t happen with the new cast iron saw.

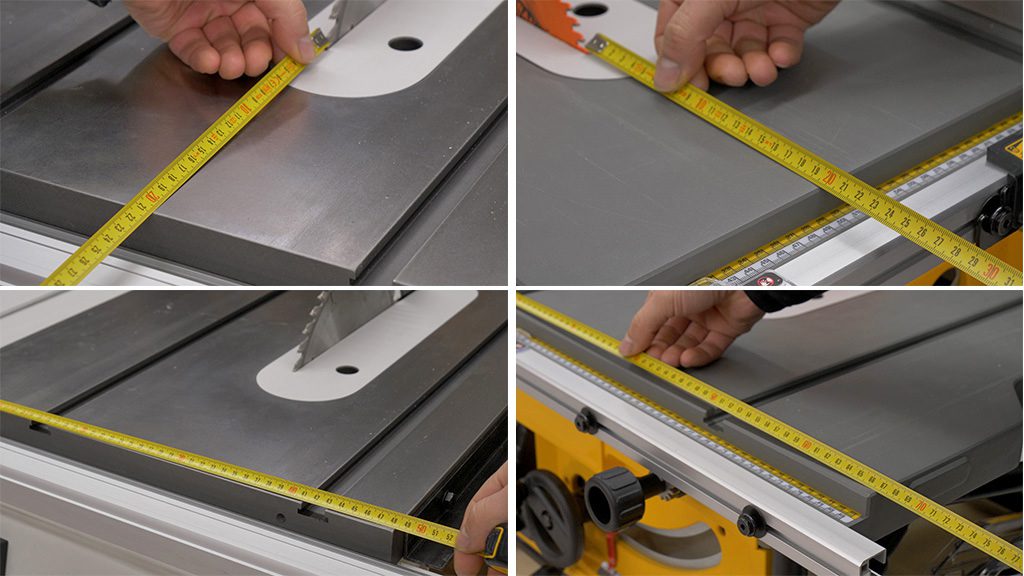

The other saw’s fence is quite robust and precise. Logically, it would be more so if its aluminum profile was iron instead and it had a T-square system. The rip capacity of the Dewalt is about 83cm. In the Axminster it depends on the length of the aluminum profile of the fence. In my case, I got about 88cm of cutting capacity.

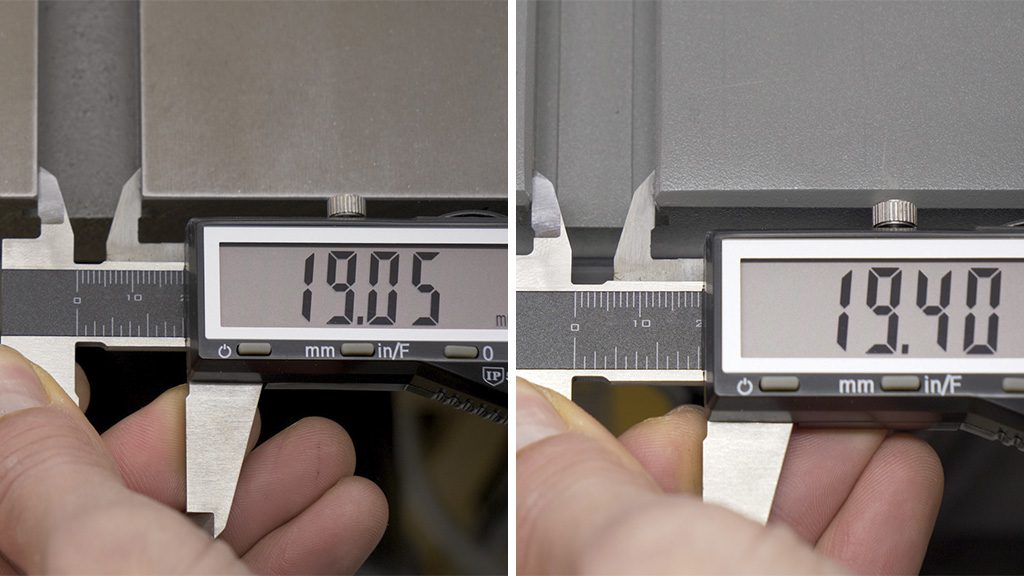

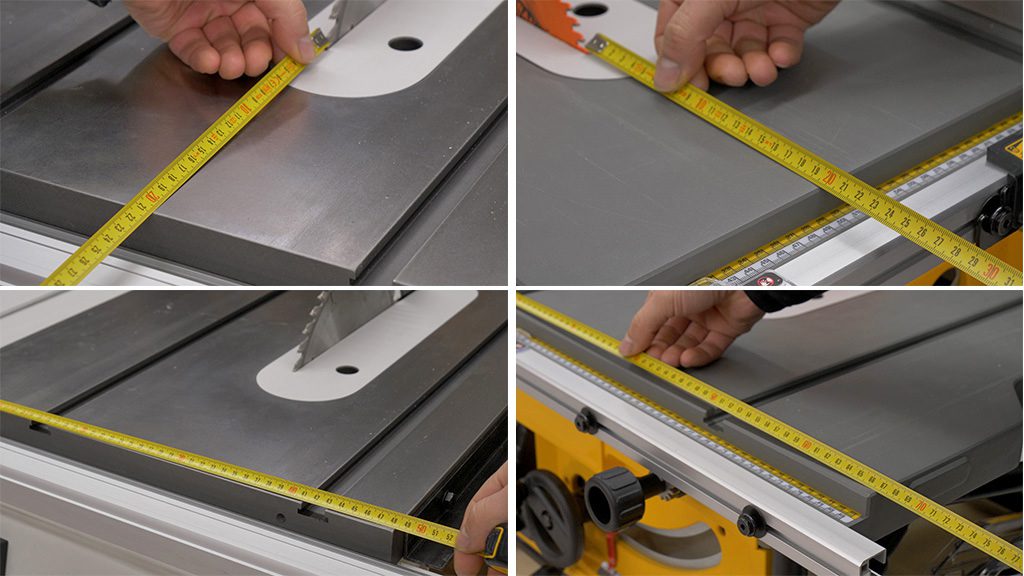

Another factor to take into account is the surface of the worktable in front of the blade, as well as its total size. A bigger surface will allow us to cut more comfortably. Both saws have a similar distance to the blade, about 21cm. I made a small infeed table for the Axminster saw fence, allowing me to reach 34cm.

The Axminster saw worktable boasts a greater depth, about 68cm, compared to the Dewalt’s 56cm. This results in a greater distance between the end of the blade and the back of the table. The width of the Axminster saw is about 48cm, while the Dewalt is about 68cm. Bench saws typically don’t have large worktables.

Table saw dust collection capacity

The dust collection system in these kinds of bench saws is not the best. The Axminster saw has an outlet for a 100mm tube, which can be connected to a crown guard with a 63mm tube. Since I’m not going to use it, I made a plywood cover.

The Dewalt has a single 63mm outlet which can be fitted with an attachment to reduce it to 35mm. In these shots you can see the entire motor and dust removal system is fairly weak, and you could easily end up moving the blade.

What kind of table saw should I buy?

I don’t think there’s one single answer to this question. Each saw has its own advantages, but in my opinion, for the kind of projects I do, the cast iron table saw offers more advantages than the jobsite saw. Ideally, perhaps, we should have both kinds of saws, but if you can only have one and you’re not going to use it outside your workshop, I recommend trying a model with a cast iron table.

If it’s necessary for you to take your saw outside your workshop and you can only have one, the most logical course of action would be to go for a jobsite saw with a cast aluminum table.

Jobsite saw prices tend to be much lower. In this case, since the Dewalt saw is among the most expensive of its kind, and the Axminster is among the cheapest and most simple of its kind, the difference isn’t that big.

Almost all cast iron saw tables have a cabinet stand that goes all the way to the floor. These bench saw models usually also offer the option to attach an iron stand, often with wheels. They are also sold with extensions so that you can have a bigger worktable. In my case, since I installed it in the workbench, I haven’t used them.

That’s all for today. In a few days I’ll post the second article on the modifications required to use this saw with a cast iron table with the Mobile Workbench. I’ll be showing you how to change the bench’s worktables to adapt them to the new saw.

Thanks for that excellent comparison. I recently agonised about which saw to buy, but in the end it was an easy choice. Trying to keep cast iron from rusting in my “shop” is pretty much futile, so I went for the the smaller DeWalt.

I’d prefer cast iron as a table, and I really like the geared blade angle adjuster. It took me a while to get my 90 and 45 degree stops set but, fingers crossed, they’ve not shifted.

So far I’m delighted. The wet November would’ve meant a cast iron table would be rusted up, despite my best efforts.

Read/saw yr blog/videos with interest as i am considering swapping my dwe7492qs with the axminster aw254ts. As far as i can see the arbor on the aw254ts has a 5/8 arbor but the flange on the arbor has a 30mm ridge and as far as i can see/determine you grinded down a little of the arbor. Was this in order to be able to fit some dado blades ? Could it be an idea to grind the whole flange to 5/8 so you could a get a little longer arbor but still be able to use 30mm bore blades using the Dewalts outer flange. Would this be difficult to achieve.

Your comments will be highly appreciated.

Stan

hi Stan, I understand your question, but I think you can only gain another 2 or 3mm of shaft. I dont think it’s worth it. The short shaft of the aw254ts saw is clearly a disadvantage.

Are there any Axminster alternatives for table top, castiron saws that are available in the United States?

hi Brian, check out the SawStop CNS175-SFA30