Today I’m going to make this folding knife using recycled materials, which will be useful in my workshop. I drew inspiration from the so-called taramundi knifes, fomous in Spain. They don’t have a locking mechanism, the friction between the wood and the blade works like lock.

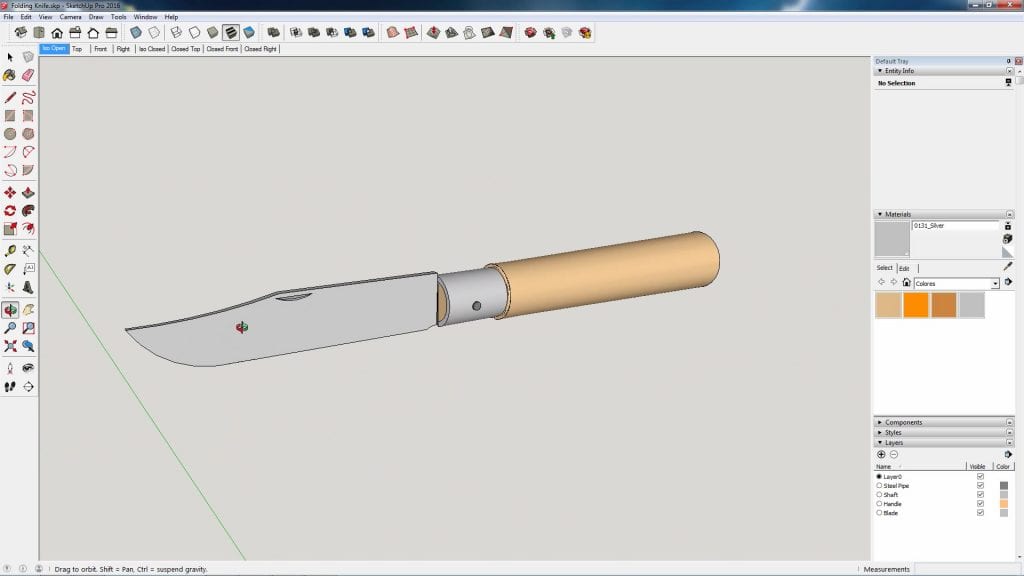

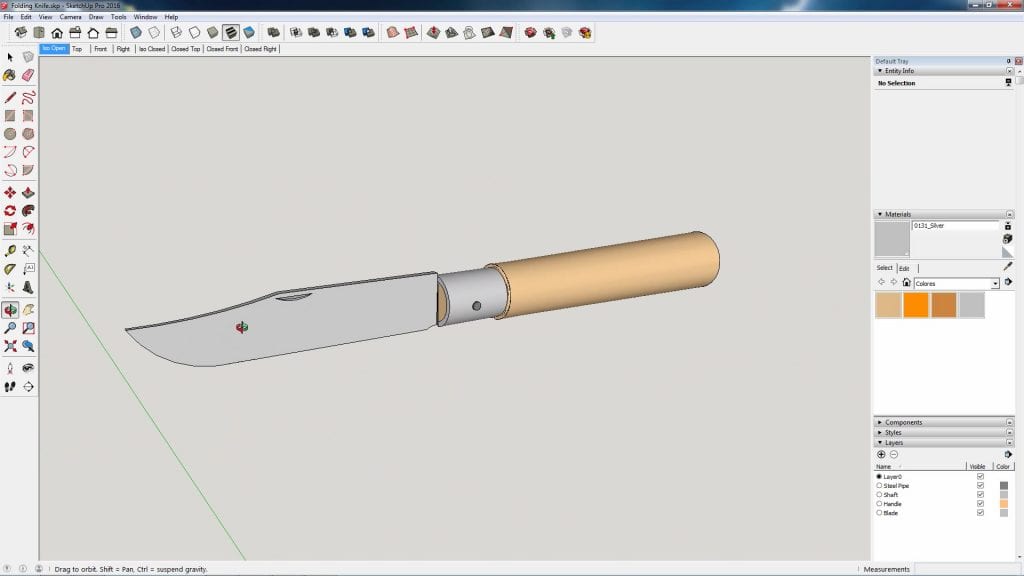

In this SketchUp file you can see how simple the design is and how easy it is to make. It’s made up of just four parts. First I’ll cut this olive piece for the handle.

DIY Folding Knife Plans

I’m going to detach the lathe’s sanding station so that I can turn the handle. After marking the centers, I load the olive wood into the lathe and start shaping it with a roughing gouge. I’ll leave some parts unturned on both sides of the workpiece so that I can use them as support in the next steps of the machining process.

This part will be used to insert the steel tube. I check the measurements with a caliper, finish shaping the handle and take advantage of the lathe’s rotation to sand the wood.

With the table saw I’ll cut a groove on the handle to insert the blade. I check the height with the caliper and adjust the disc’s height. We must make sure the groove is made in the center of the wood.

Then I’ll cut a groove in the steel tube and cut it down to the required length. After sanding it a little, I insert it into the handle and, with a piece of the same thisckness and material I’ll use for the blade I make sure everything’s correct.

Now it’s time to drill a hole for the pivot. I’ve prepared this template that will help me do the job.

Making the blade:

Now I’ll cut the blade of this old HSS steel disc. I’ll use an angle grinder.

I reattach the sanding station onto the lathe to finish shaping the blade, first with the disc sander and then with the belt sander. Then using a dremel I make a notch allowing us to release the blade more easily.

Now it’s time to drill a hole for the blade to pivot. I’ll use the hole on the handle as a guide to mark it. As I thought, this step won’t be so easy. The bit and the disc are made of the same material, HSS steel, which makes it impossible to drill the hole like this.

Not even with oil or starting with bits of smaller diameter. Perhaps a sturdy column drill at lower RPMs…

I’m going to solve this problem the fast way. I’ll make a groove with the dremel, since it will barely be noticeable in the finished product… And now I’ll try again. There don’t seem to be any problems this time. By taking this approach, there is less material to drill through and the drilling process is thus made easier.

I’ll prepare this template with the exact edge angle I want for the blade and stick it with double-sided tape. After shaping it on both sides, I finish sanding it on a flat surface like this. I’ll start with P120 sandpaper and finish with P500, lubricating with water and sanding untill all the visible scuff marks are gone.

I’m going to mount this polishing disc on the lathe’s shaft, allowing me to obtain a more professional finish. Now all that’s left is to assemble all the pieces. I put in the nail that I will use as pivot and cut off the part that’s left over.

I’ll strike both heads of the nail like this. They will deform and lock the nail itself onto the steel tube, as well as tightening the blade against the wood.

Looks like I tightened the pivot a bit too much, but since the olive wood was a little dry, it will turn more smoothly in a few days. In fact, in dry environments it’s normal for thid kind of blade to loosen up given time. It can be fixed by striking the head of the pivot in the same way.

I apply a couple of coats of oil varnish and here’s the end result…

After testing the knife on several kinds of material, the edge of the blade seems to be holding up quite well. Take a look at this other article to see the folding knife in action!

Well the easiest way to drill a hole to that steel is to normalize it… and do some heat treatment and tempering to your steel project.

Not that easy in HSS, it is engineered to retain high hardness even after being red hot; however, an easier way is to use Bosch Multiconstruction carbide tipped bits.

I have drilled fully hardened tool steel with them for handle scale pins onfixed blade knives. Have also seen carbide masonry bits sharpened and do the same

thanks for the tip!

That is… absolutely awesome workstation!

Nice folding knife! Although I would be afraid to use it as it has no locking system to prevent it from folding.

thanks!

Gorgeous and classy design! I love the olive wood so much…the grain is stunning. Another cool way to upcycle that saw blade. 🙂

thanks mate!