What is HPL? (high pressure laminate)

HPL stands for “high pressure laminate.” In my opinion, it’s an incredibly versatile material. After I became familiar with it, I started using it in many projects.

You could say it’s the extreme version of MDF. It’s made by impregnating several layers of kraft paper with phenolic resins and subjecting them to high pressure and temperatures during the manufacturing process. Don’t be fooled by the name “paper,” the resulting material is quite hard and heavy, looks somewhat like plastic and is dark brown.

Usually, decorative layers are put on both of the outer sides, usually made with decorative paper coated with melamine resins. It can also be a wooden or metal layer. The core of the board can be colored for use in projects where the edge is visible.

HPL comes in many sizes and thicknesses. The most common of the latter are 3, 5, 8, 10 and 15 mm. The boards are usually 250 x 125cm, although other sizes are available. A board that size that’s 15mm thick weighs around 60kg. There’s a kind of HPL that’s marked “G” that can be used outdoors, and another one that’s marked “C”, for indoor use.

It’s a fairly expensive material. I find small discarded scraps of it in the waste skips of factories that make furniture for pools, hospitals, etc.

In Europe, a kind of laminate sheet, commonly referred to as “Formica” (a name given to it by the company that marketed it) is widely used. These sheets are usually 1mm thick. Factories often glue them to the sides of any board, but you can also find it in rolls that you can use in your workshop to customize your boards. Normally, it has a decorative laminate impregnated with resins on its outer face, while the other face is rough to improve its adherence when gluing it on a board or other materials.

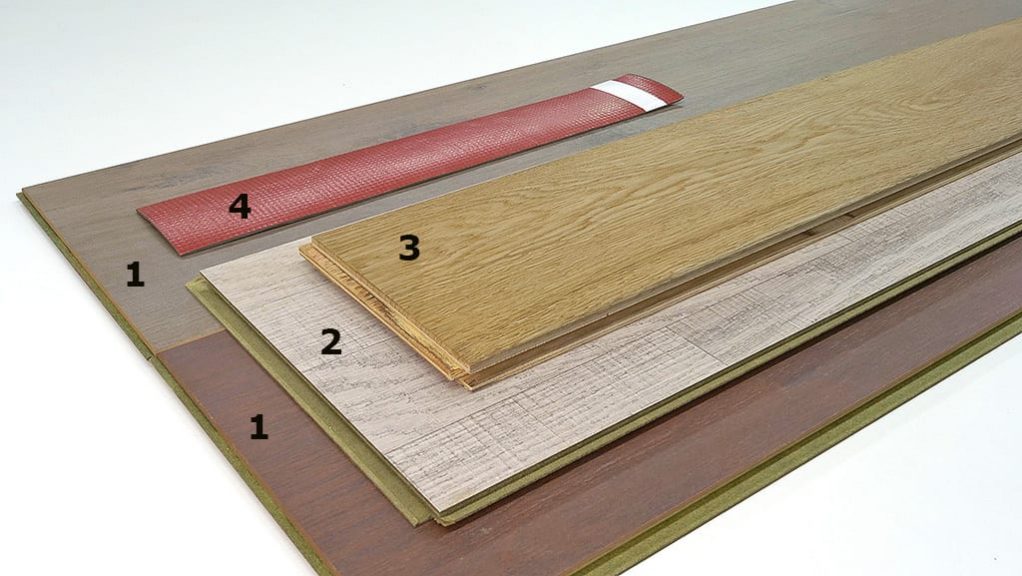

Types and Styles of HPL Board:

These are some of the HPL boards you can find in a carpentry store:

1- 6mm thick HPL panel with a decorative dark grey sheet impregnated with melamine resin on both sides.

2- 15mm thick HPL panel with a decorative light grey sheet impregnated with melamine resin on both sides.

3- 8mm thick HPL panel with a decorative faux concrete sheet impregnated with melamine resin on both sides and with a black-tinted core.

4- 8mm thick HPL panel without a decorative sheet, black-tinted core.

5- 0,5mm thick HPL sheet veneer with a faux wood decorative laminate, impregnated with melamine resin. You can also see its other side, with a rough surface to improve adherence when gluing it.

Uses of HPL Board:

Since this material has low porosity, is hypoallergenic, resistant to high temperatures and moisture, as well as stains and scuff marks, it’s the ideal material for intense use, such as lockers, dressing rooms or restrooms in public pools or sports centers.

It’s also suitable for furniture in humid areas such as bathrooms or kitchens. HPL that’s marked “G” is suitable for outdoor use and is ideal to build playgrounds, outdoor furniture and facade lining in construction.

Next time you’re having a coffee at the terrace of your favorite café, take a close look at the table. It’ll most likely be HPL.

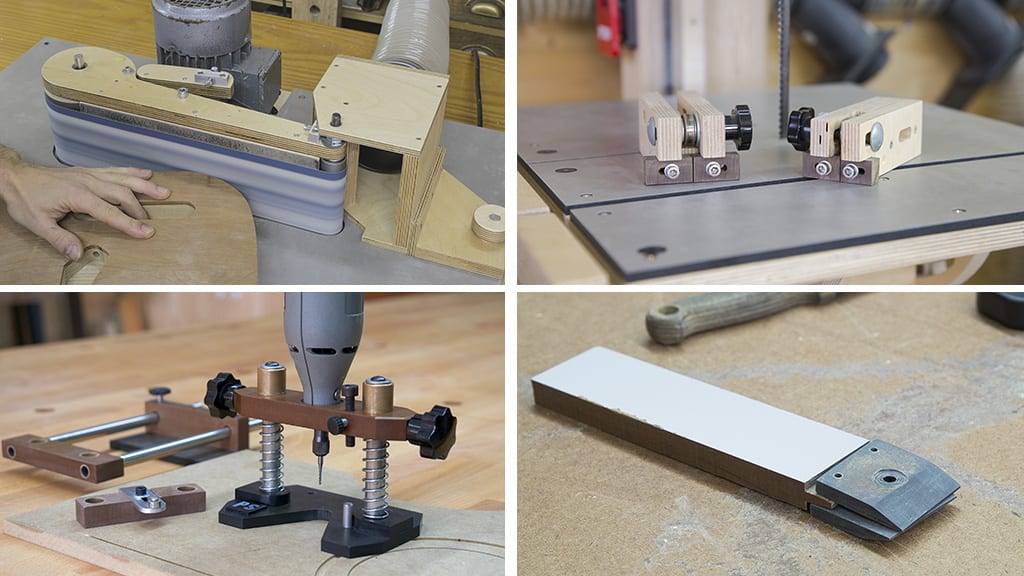

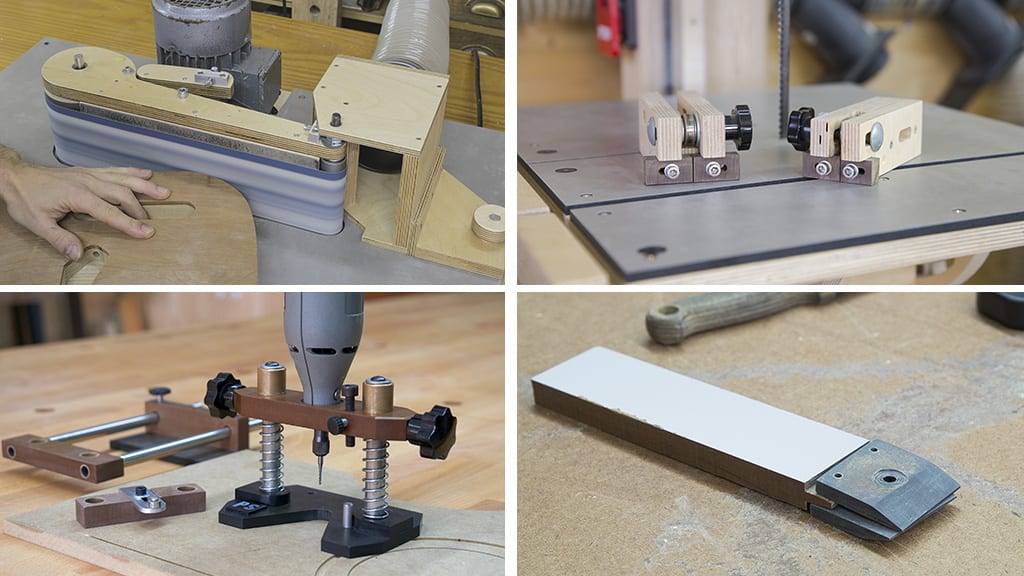

Besides its usual purposes, I’ve used HPL in many other ways. Since its surfaces are so smooth and stiff, I used it as table for many homemade tools. An example is my home-made edge belt sander in the first picture.

A few months ago I also used HPL to renovate the blade guides of my homemade band saw, and also to improve its table, as you can see in the second picture.

HPL panels are also perfect to make small pieces for tools that require firmness and precision, like a plunge base, for a Dremel-type rotary tool. You can see it in the third picture.

Another similar case is in picture 4, where you can see me building a jig to hold knives and sharpen them safely with my homemade knife sharpening jig.

I’ve also used HPL laminate sheets in some of my projects, especially to reinforce the tables of some of the tools I built. In the first picture I’m cutting a sheet that I’ll later glue to my bandsaw’s table, you can see the results in the second picture. I always use contact glue for laminate sheets, but ideally, a hot plate press should be used.

I did the same with the table of my thickness sander, as you can see in the third picture.

And last but not least, I should mention the work of a good friend of mine, who uses HPL panels to make surfboard fins. Since they’re machine-relieved, you can see the paper layers that make up HPL in the picture; they kind of look like wood grain. If you want to see more of his projects, check out his website.

Processing of HPL Board:

As you have read in this article, HPL panels are a highly versatile material, not least because you can work with them using woodworking tools and thread them the way you would aluminum, although they’re considerably heavier.

But although it’s possible to process it using woodworking tools, it’s much harder to cut and route than wood. When the tool allows it, it’s advisable to lower its speed to a medium range, both for cutting discs and router bits, and proceed slowly.

In the first picture I’m cutting a 10mm thick HPL panel screwed to a hard plywood panel, using a disc with lots of teeth, with great ease. In the second picture I’m sanding the edges of a small piece with the disc sander. HPL usually gets lots of marks around the edges after being cut with a disc.

In the third picture I’m drilling a hole with a 20mm bit in a 15mm thick HPL piece. I lowered the speed to a medium value and proceed slowly to avoid burning the bit and the HPL.

In the fourth picture I’m threading a piece of HPL with a thread tap, predrilled with a bit 0.75mm less wide than the screw. As you can see in the picture, I also sanded down the melamine on both sides of the HPL and polished the entire piece with a polishing disc and polishing compound.

Here you will find a post in the forum with interesting information about where to find for HPL board:

interesting material, where can I get it?

hi Saul, check this out: