What is particle board?

Particle board is made from small wood shavings or chips, glued together with urea-formaldehyde. The manufacturing process is quite similar to that of MDF, but without shredding the shavings into fibers. It’s also necessary to remove the bark before reducing the log to chips. Nowadays, leftover pieces of wood from carpentry shops, pallets or sawdust are used to make particle board.

After drying the chips, they are sorted according to their size and mixed with urea-formaldehyde. Different proportions of glue are used for the different types of board, waterproof, fireproof or normal. Once they’re damp with glue, the chips are placed on metal plates. The first and last layer are fine chips, the middle one is thicker. This is done in order to achieve a better finish on the outer faces of the board. Finally, pressure and heat are applied to form the board.

It’s available in many thicknesses, the most common of which are 8, 10, 13, 16, 19, 22, and 30mm. Particleboard is usually 244cm long and 122cm wide. The weight of an 18mm thick board with the above measurements is around 32kg.

This is arguably the board where it’s easiest to see the difference in quality at first glance. The quality may vary depending on many factors, for example, the amount of glue used and how it was distributed, or the pressure applied on the board, making the shavings more or less compact.

The ones you can buy in large DIY stores are usually of really poor quality. You can test this yourself by trying to peel off the shavings with your fingernails. You’ll likely be able to scrape them off without much effort. You’ll also notice they’re lighter, especially if you work with them –they pretty much fall apart in your hands. Particleboard is a very cheap board, so unless you want to buy a huge amount, always try to buy a quality one waterproof particleboard.

It’s widely used in all kinds of interior carpentry in Europe, for example, to build kitchen cabinets and the inside of built-in wardrobes. It’s also used to make affordable mass-produced furniture, not used as much in other parts of the world, such as the United States.

Types of Particle Boards:

These are the main kinds of particleboard you can find in a carpentry store:

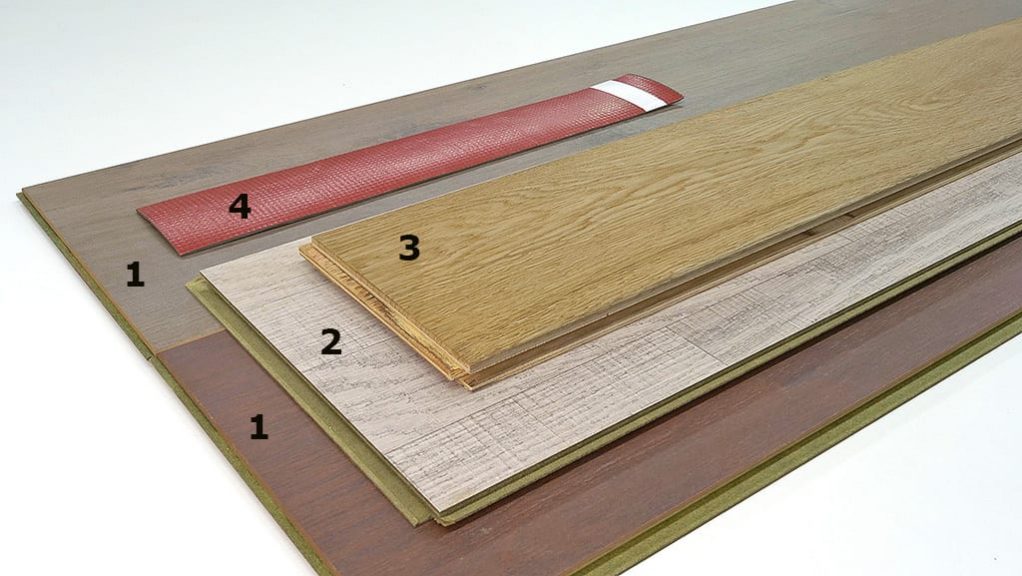

1- Bare particleboard, the cheapest of the bunch. You can see the chips at a glance, even on the outside. They’re quite big and not too compressed. This one is 10mm thick. It’s normally used as protection, to make packaging and crates.

2- Particle board with melamine on both sides, 16mm thick and waterproof. Just like MDF, it’s painted green to distinguish it from the normal version.

3- Particle board with melamine on both sides, but in this one the melamine imitates oak wood. Just like the previous board, it’s 16mm thick and waterproof.

4- Particle board with a pine wood veneer, there is a wide variety of veneers. Just like plywood, veneered particleboard becomes thicker. For example, the 18mm board becomes 19mm thick. This one is not waterproof.

As you can see, almost all kinds of boards come in normal, waterproof and fireproof versions. If possible, it’s best to always buy waterproof boards.

Uses of Particle Board:

Just like MDF, I don’t use particleboard all that much. Only in the interior of some pieces of furniture like kitchen cabinets, where I’m not interested in painting the interior, so I use particleboard with melamine, either white or faux wood.

In the above pictures, I’m installing a kitchen made with waterproof particleboard, with white melamine. It’s a very practical material for these kinds of jobs.

That was also the case with the interior of the open wardrobe. This time I used particleboard with white melamine bought in a large DIY store, which was a big mistake. It wasn’t waterproof and it practically fell apart after barely touching it.

In the fourth picture I’m screwing in the back part; it’s an MDF board with melamine on one side, and on the other it’s faux oak wood.

Processing Particle Board:

Particle board isn’t the best material to work with, either; for several reasons. First off, it wears out discs and router bits much too quickly, because the inside is filled with traces of sand or even scraps of metal. The worse the board is, the more this will happen.

When cut or milled, it produces a lot of dust, and also shoots off pretty big chips. I’ve gotten hit in the face by some of these splinters or chips, and I can assure you it’s not very pleasant. To work with this material, you absolutely need safety glasses and a mask.

In the third picture I’m gluing white edging to the board. Unlike MDF, the edges of particleboard cannot be exposed, or painted or milled into a shape. Also, we must apply edgebanding when we’re using veneered particleboard with edgebanding of the same wood as the board.

It’s easy to put screws in, both into the face or into the edge, which is what I’m doing in the third picture. You must simply drill a pilot hole with a bit 1mm less wide than the screw.

Another disadvantage is that melamine splinters or chips easily when the disc cuts through it, which you can see in picture four. This applies to all kinds of boards with melamine, but it seems to be worse with particleboard. One trick that can mitigate this problem is to put some masking tape on the board before cutting on the areas that the disc will cut. Needless to say, you can minimize the problem by using a sharp disc with lots of teeth and advancing slowly. Depending on the project, you can leave these chipped faces on the inside or in areas that won’t be seen when the furniture is assembled.

Another option to minimize it is to simply buy pre-edgebanding board strips from a manufacturer, very common in carpentry stores, at least the ones that are 58 and 33cm wide and 16mm thick, used in kitchen cabinets and cupboards. This will also make the construction process of your projects easier.

Some professional table saws have a scoring blade that cuts a few tenths of a millimeter into this part of the board before the main disc, to avoid the splintering problem.

I did not know that this board is used to make kitchen cabinets!

yeah!