Update: The two things you should take into account when buying a blade for your circular saw or table saw is the maximum diameter that your tool can be equipped with and the diameter of the shaft. CMT usually has three blades like the orange that you can see in this article for each diameter.

1- One with few teeth to rip solid wood lengthwise; this blade does not make fine or clean cuts.

2- Another with lots of teeth to make crosscuts in solid wood. Also for all kinds of cuts in MDF, plywood boards or boards with melamine achieving very fine cuts.

3- Finally, there’s another blade with a medium number of teeth which could make most types of cuts, without being as good at the aforementioned cuts. Ideally you should have all three blades so that you switch between them for each kind of cut, but if you can’t buy all three, the medium one is the best option. To figure out the number of teeth, look at the “Z” reference (Z40, Z60, Z80, etc).

Hi, I just received a new fine cut-off circular saw blade, so I am gonna take this opportunity to try to explain, as some of you have requested, the pros and cons of the three blades I got now.

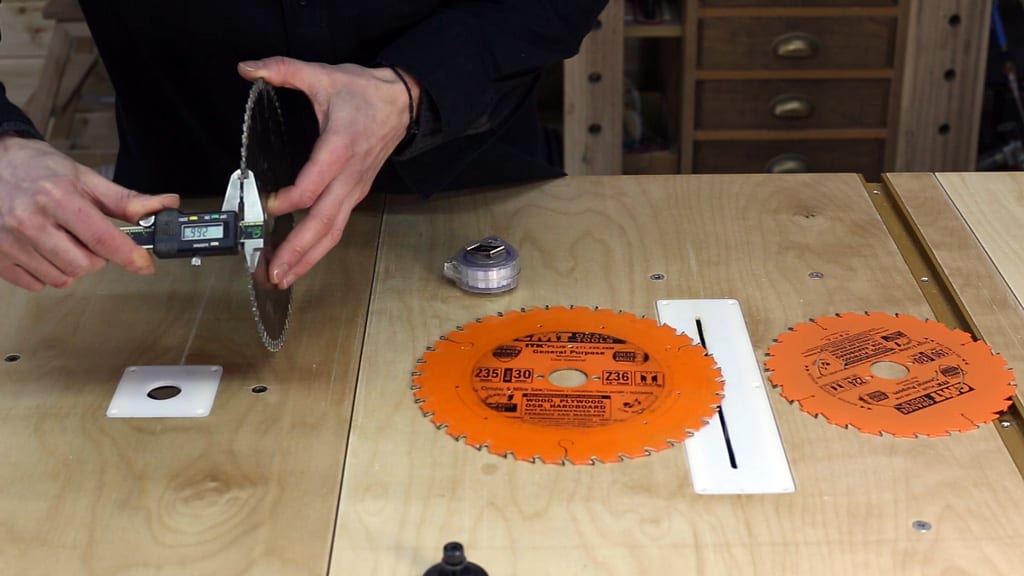

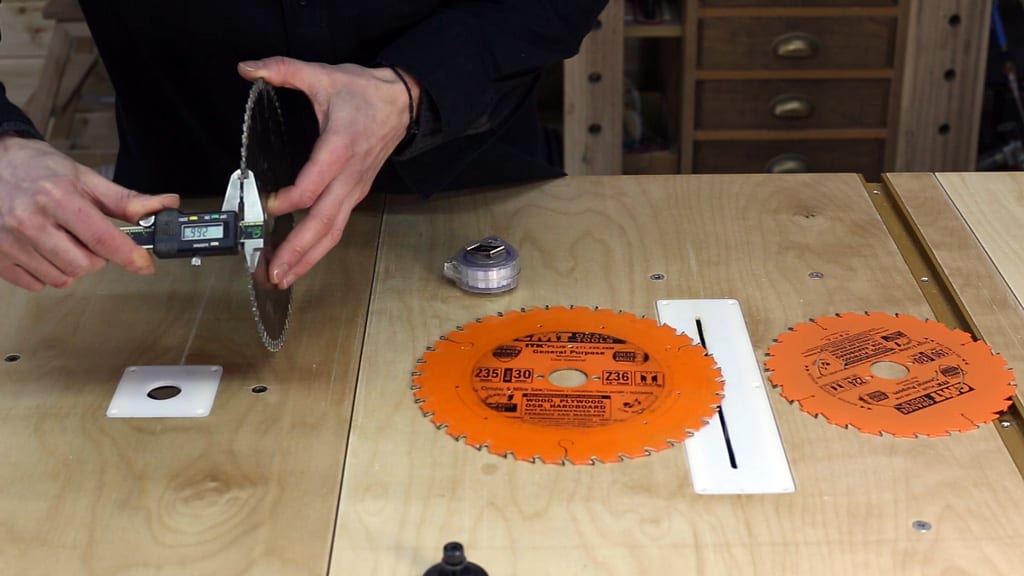

This is the one I am using right now. Is the bigger diameter I can mount in my circular saw. And as you can see, being that big and thin, it can tilt a bit.

Other common problem people usually have with inverted circular saws, is keeping the squareness of the blade with the table, specially at low cutting heights because the clamping system becomes more unstable the lower the blade is, and it produces tilt due to the weight of the motor.

This problem will increase as the quality of the machine decreases. With mine this issue is almost imperceptible.

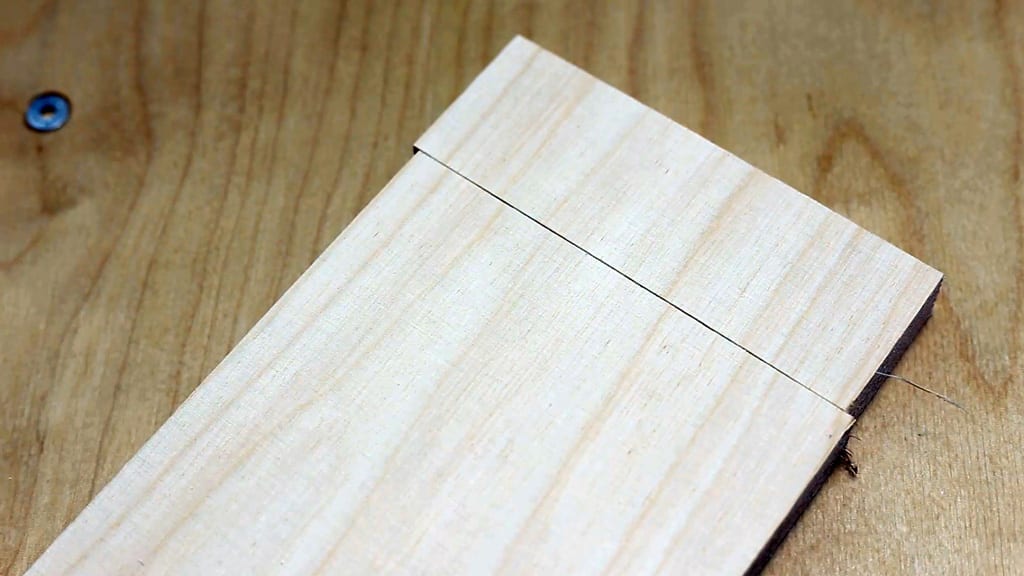

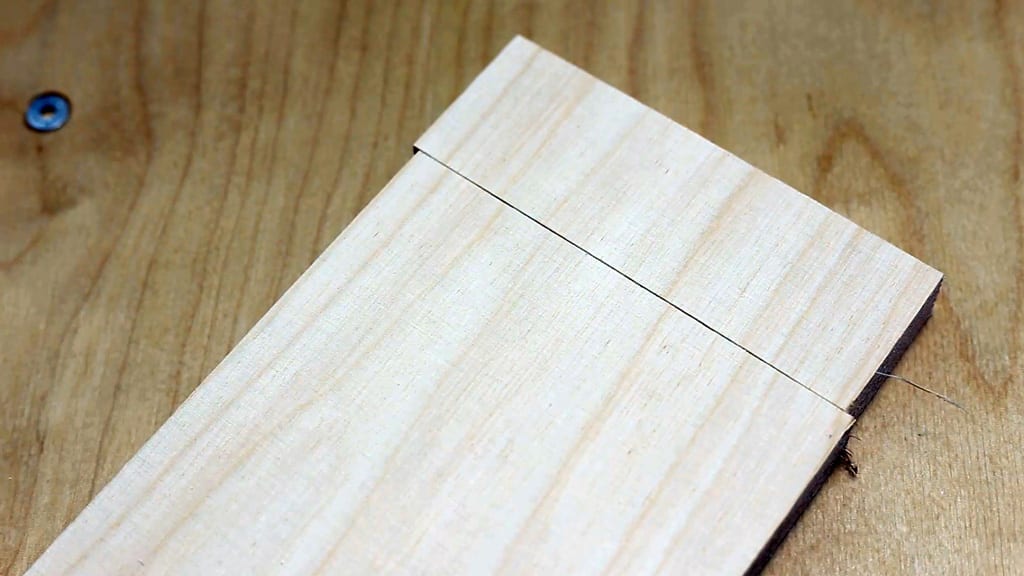

I am going to make a cross cut so you can see the tilt I was talking about. It is not easy to see throug the camera but it actually exists.

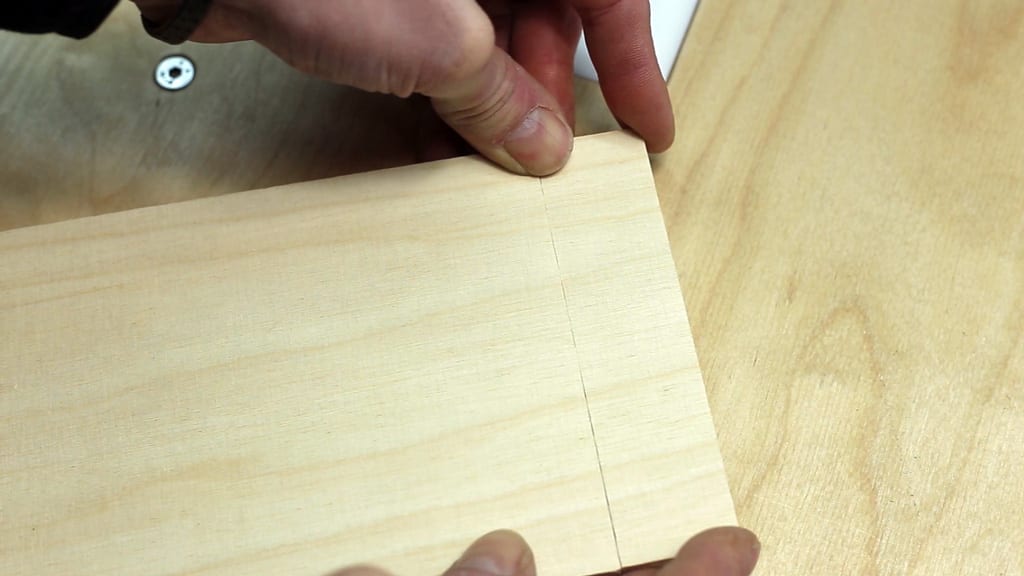

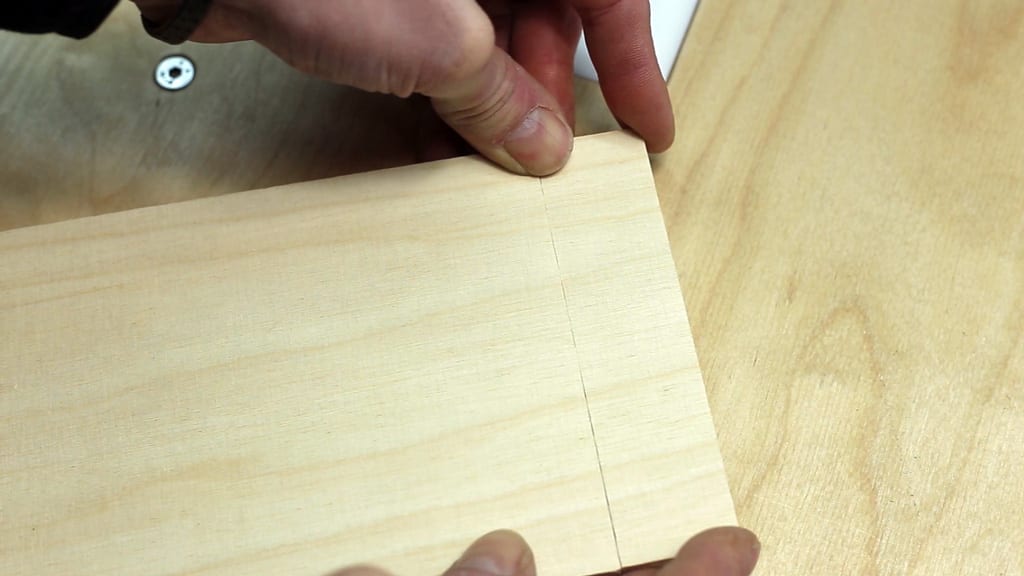

And I am gonna try the new one. Of course never forget to unplug the electrical cord from the wall outlet first. As you can see the quick access cover makes the replacement of the blade a lot easier.

The start is much smoother because of its lower weight and diameter and there is no tilt at all. Besides, being smaller, I can keep the circular saw in higher positions avoiding the squareness problems I was saying before.

As this kind of circular saws do not have speed control, it is important to choose the right blade for every type of work. As a rule, the harder the material is, the less revolutions you got to use. So in our case we will use blades with a lower number of teeth.

This is the new blade, it has a diameter of 190mm and 24 teeth. I’ll use it mainly for wood and wood-based materials like hard plywood. I get a maximum cutting height of 52mm.

It is just 1,8mm thin so it wastes little material and as the friction is lower you need less power, so it is perfect for rip and cross cuts at high speeds.

This one is like the other but with a bigger diameter of 235 millimeters with 36 teeth. I get a max height of 70 millimeters so I’ll use this one with the higher pieces of wood and wood-based materials like hard plywood.

The last one has a diameter of 208mm, a thickness of 2.65mm and 64 teeth. I am gonna use it for laminated boards, Mdf and melamines. Because as you may know, with this dedicated materials you need to use blades with a higher number of teeth.

There is another subject that will be interesting to discuss and share with us . About to prevent the table saw kickback! Using the feathers is not practical all the time. The handsaws have no blade splitter . What about to install a splitter in the aft of the blade? And also will be nice your opinion of using those special “DADO blades to cut the dados”Thanks a lot and bestregards,

Dorel

thanks for the comment Dorel! you’re right, I have to make a video to explain those problems.

For making different nice and creative design on wood, we always love to have the assistant of circular saw. This is absolutely effective post. Thanks you

thanks Adam!

It is great to have such information that enrich us. Lets have more details on these topics that will help us to use and get benefits from Saw. Cheers!