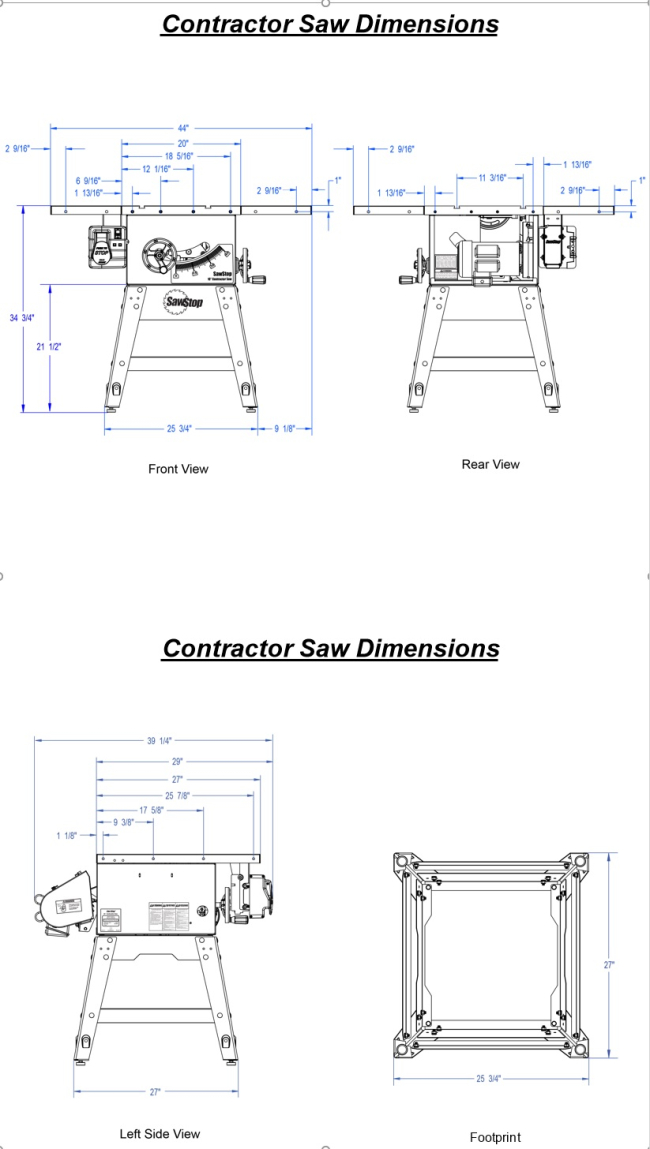

The CNS table is 20” x 27” (508 x 686mm) and the saw is 13 ¼” tall (337mm). It comes with two stamped steel “wings” that are each 12” x 27” and attach to each side of the table (SawStop sells cast iron wings as option accessories). The instruction manual (which is quite detailed) comes with a nice graphic showing overall imperial measurements.

The T-Glide system uses heavy steel rails that attach to the front and back of the table. Another steel frame mounts on the front rail for measurement, with the fence to riding on the front frame and rear rail. The frame and rails extend past the right of the table and wing through an extension table which I won’t be using. There is a “36 inch” and “52 inch” T-Glide version available… which refers to the cut length available to the right of fence. As both versions allow for up to 12” inches left of saw, both are very long. The “36 inch” rail is about 1610mm long, and the “52 inch” rail is over 2m long. The local shop had a SawStop cabinet saw setup with the “52 inch” system (photo, extension table not installed), and when I saw it realized it was entirely too long for this project. I purchased the shorter “36 inch” T-Glide system.

The workbench will need minor adjustment for the CNS for the workbench depth to account for the deeper table (680mm vs 686 mm) and the height. Beyond that there are a several other issues to account for. Like the Axminster, the SawStop blade height adjustment handwheel is along the right of the saw cabinet body. The switchbox is designed to mount under the left extension wing and isn’t integrated into the saw body. The motor projects out the back of the body about 255mm. Lastly there is a dust collection shroud which protrudes from the bottom roughly 4cm, which is fine if the saw is resting on a frame or rails but means the saw can’t rest on a flat plane (photo of bottom to show dust collection shroud).

The T-Glide rail and frame will also need modification. Using the saw without the left steel wing, they will intrude on operation of the sliding carriage. Mounting the rails as normal, but cutting them off where the left extension wing would normally be, shortens the T-Glide rail to about 1525 mm [edit: correct measurement is 1310mm] which seems more manageable but would still extend past the right end of the workbench without other modifications.

So overall my adjustment needs are:

- Adjusting depth of bench for saw

- Determining mounting option for saw to account for height and dust shroud

- Adjusting for motor protruding into outfeed table

- Accounting for saw height handwheel

- Accounting for switchbox mounting

- Determining length and mounting of T-Glide system

While all of these can be accommodated, I will think about options. The motor mounting is probably not something I want to change, and I’ll have to think about considerations for the outfeed table.

For the handwheel & switchbox, using both factory steel extension wings and extending the center section to account for the increased width is easy from a design standpoint but makes the bench longer than I’d like for practical purposes. Another option would be extending the router table (similar to the Axminster) into the central portion to allow for the handwheel as well as building a dedicated switchbox mount while shortening the “carriage stop” drawer a bit. Finally, I’ll have to determine how much of the T-Glide rail I want to keep.

Thanks in advance for any comments/suggestions. I’m looking forward to this project.