Page 1 of 2

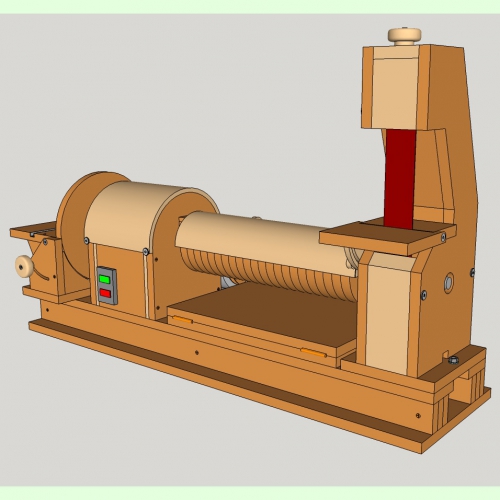

My new lathe sanding station

Posted: Thu Jan 26, 2017 3:13 pm

by Suso

Since turning is not a very common operation in my workshop, I've thought about getting more use out of the engine by adding a Belt Sander and a small Thickness Sander.

More info:

My new lathe sanding station

Posted: Thu Jan 26, 2017 6:27 pm

by Sanfra

Excelente, como siempre es digno de admirar tu trabajo.

te felicito, y quedo a la espera de mas, jajajajaa.

te admiro y por eso te sigo.

Abrazo.

My new lathe sanding station

Posted: Wed Feb 01, 2017 7:06 pm

by Sanfra

Hola, yo nuevamente, acabo de mirar el segundo video, admirable, simple, prolijo y perfecto.

como siempre, es una sorpresa y un deleite, seguir tus trabajos.

nuevamente Felicitaciones.

My new lathe sanding station

Posted: Thu Feb 02, 2017 10:06 am

by Suso

muchas gracias Sergio!

me alegra que te gusten mis diseños.

My new lathe sanding station

Posted: Fri Feb 17, 2017 10:05 am

by Sanfra

Hola Suso, buenos dias.

ademas de felicitarte de nuevo jajaja, queria preguntarte, si el sistema de aspiracion que implementaste, es suficiente???

va, no se, que aspirador tienes, si uno comercial o uno casero, es que tambien estoy tratando de fabricar mi "duster colector", jajaja.

bueno muy buen trabajo, impecable como siempre.

un abrazo.

a ya que estamos, me gustaria que en un futuro comiences el diseño de una sierra sinfin, mediana, jajaja perdon por pedir jajaja, pero siempre haces lo mejor y seria interesante de ver, eso confeccionado por ti.

ahora si, no molesto mas, felicitaciones.

My new lathe sanding station

Posted: Fri Feb 17, 2017 2:41 pm

by Suso

Hola Sergio,

tengo un aspirador muy viejo y normalito del Lidl, no aspira gran cosa y aún así con este diseño apenas deja escapar nada de polvo. Tengo en mente hacerme con otro, o al igual que tu fabricarme mi propio "duster colector" y de este modo te puedo asegurar que será mas que suficiente!

La sierra de banda es uno de mis proyectos pendientes, espero que pueda llevarlo a cabo este año...debes estar atento! :D

My new lathe sanding station

Posted: Mon Feb 20, 2017 7:30 pm

by Daniel2

Hi Suso,

Daniel from France ... so I finally bought the plans for the Lathe, waiting for the thickness sander ones too.

A few comment, first w.r.t. the rotation, for the lathe that's normal, but I think for the thickness sander it would make more sense

to bring the wood piece down i.e. push from the other side. but that require the motor to run in the other direction, something

doable on most engine by providing a switch to select which pole the condo attaches to, something I will have to play with.

I was also pondering having the motor below the lathe, to take less space but that requires weakening the assembly of the

frame to let the belt go. Something else I need to think about before starting the project for good, very tempted to have a different

attachment for the motor, more like Mathias Wandel's lathe, allowing a larger range of rotation speed choices.

Can't find connector nuts in my area for that diameter of rod, so likely to just solder normal nuts together, hope that will work ...

So still a few thing to think through before I start for good, thanks again for the inspiration :-)

Daniel

My new lathe sanding station

Posted: Tue Feb 21, 2017 10:56 am

by Suso

hi again Daniel!

Regarding to the rotation of the engine, it is a good idea! I was also thinking about it, but it is quite difficult to do with my engine. There are engines which allow you to easily change the rotation, and you'll get a lathe much more versatile.

If you are going to introduce the pieces in the thickness sander from the front, you should make the tilting table much longer, because you don't have enough support at the front on the thickness sander. I think it can also serve as I did.

Regarding putting the engine under the lathe, it depends on the design you have in mind, it could be done but the way I did it also works, it is also a good idea to get a larger range of rotation speed choices.

Remember to use a perfectly straight threaded rod, some are more crooked than others, and perfectly align all bearings.

Here you can find the M20 connector nuts, I do not think it's a good idea to weld two normal nuts.

My new lathe sanding station

Posted: Wed Feb 22, 2017 11:26 am

by Daniel2

Thanks suso for all the informations. BTW for the coupling nuts most vendors around amazon are horribly

expensive (15 Euro for sending a nut !) I found way cheaper on

Ebay for europeans:

The key for the search is M20 for diameter and add "DIN 6334" as this kind of coupler seems standardized :-)

Local hardware stores had couplers but cylindrical and only for smaller diameters.

Yours,

Daniel

My new lathe sanding station

Posted: Wed Mar 15, 2017 9:57 pm

by ACME

Hola, ingresé a esta pagina por un video e hice mi cuenta pero no entiendo mucho del video.

Tengo dudas y no se si estoy consultando bien.

¿que caracteristicas tiene el motor que se usa en el video de torno lijadora?