In this article I am going to show you how I’ve sharpened the knives of my planer-jointer combo. It is the second part of this video where I have also made a new guide for the planer, if you want to see it go to the minute 6:20 of the video.

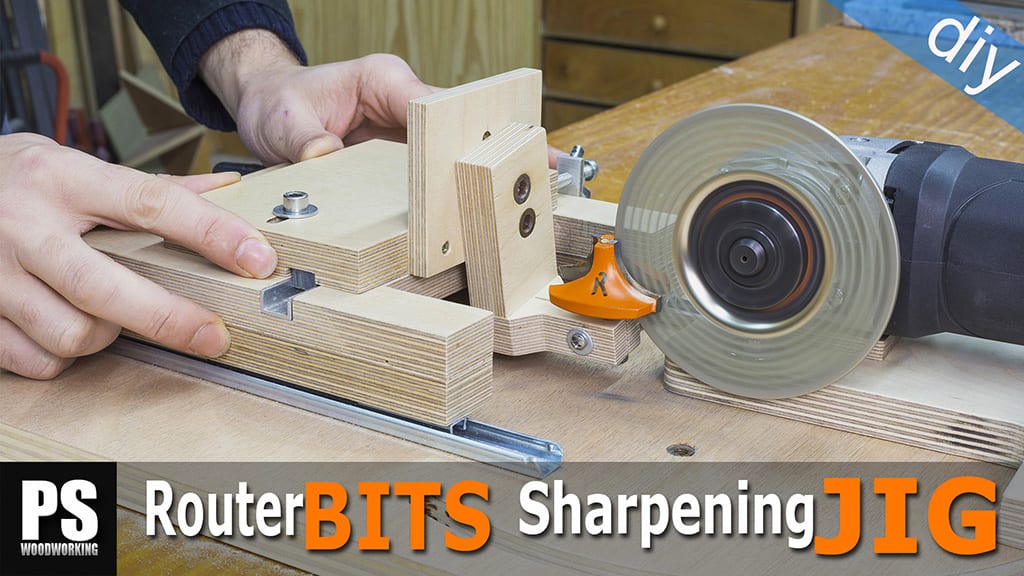

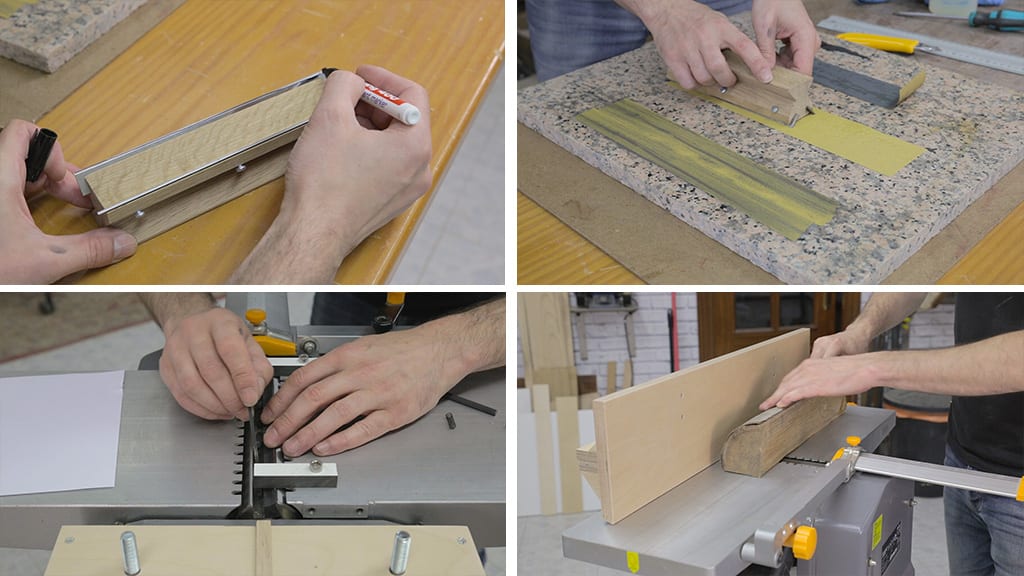

This is the wooden jig that I have made and that I will use for sharpening the jointer-planer combo knives. I’ve used a piece of oak that I had laying around the workshop and six screws. As you can see. I’ve made two grooves where I will place the knives to sharpen them against a flat surface.

This is the SketUp 3D model I’ve been working. Here you can buy and download the plans if you are interested in making your own jig and collaborate with my website.

Jointer Knives Sharpening Jig Plans

Once I have removed the knives and tightening gibs of the jointer, I clean all the surfaces with industrial-strength degreaser(third photo). As you can see, being able to detach the fence makes the operation easier.

This kind of knives is so cheap it’s not worth having it sharpened. I’ll make the wooden template where I’ll place the knives, which will allow me to sharpen them three or four times. At that point, I might as well buy some new ones because they’re so cheap.

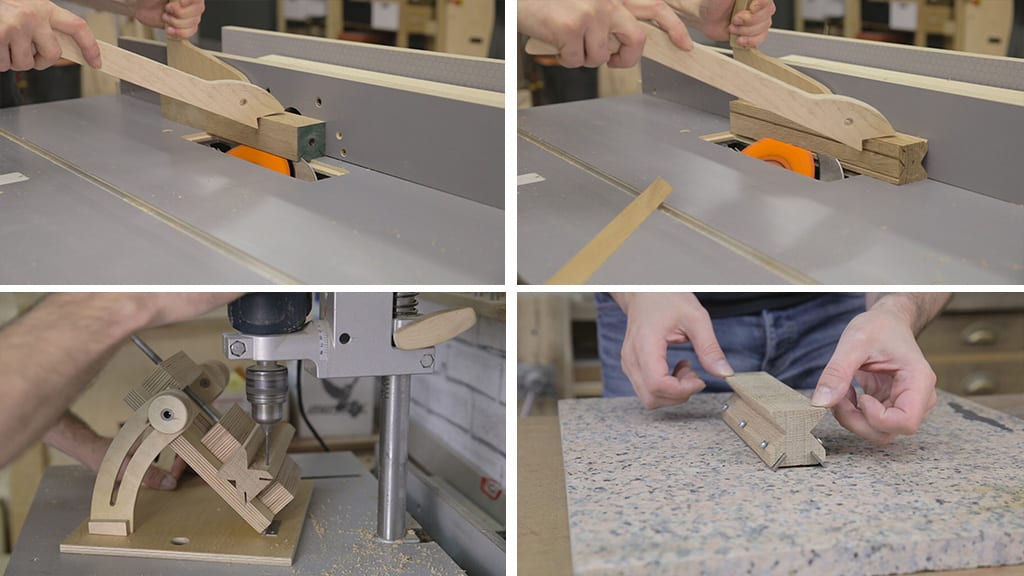

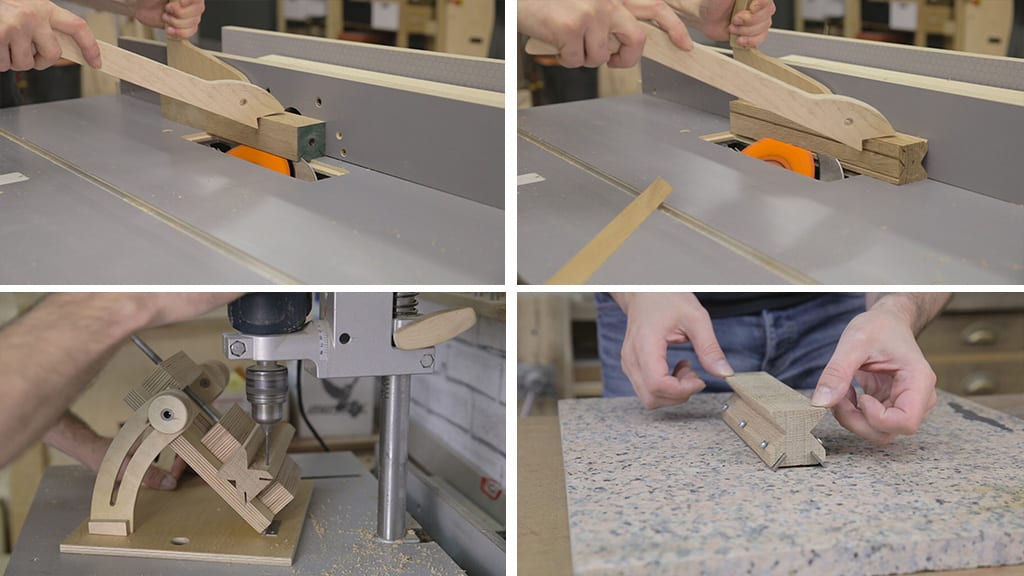

First I do some tests with the table saw to work out the exact angle of the grooves(fourth photo).

Now that I’ve found the angle, I make a template with this piece of oak and the table saw. Using a tilting vise and a column drill I make holes for the screws that will fasten the knives to the wooden block. I’ll use a bit half a millimeter smaller than the screw.

I put the screws in place and make sure the two knives are parallel to each other. It looks like we have to adjust them a little(fourth photo).

How to sharpen the knives:

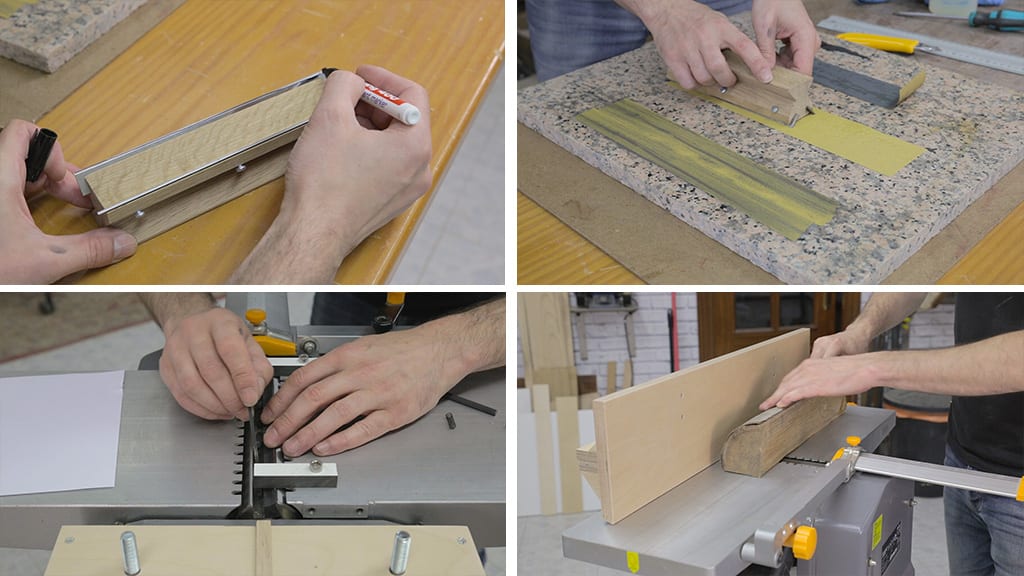

I’ll mark the edges of the knives with a marker pen to ensure I’m sharpening them correctly. We could sand the whole edge of the knive or give it a little angle on the front of the edge, as though it was a chisel.

For sharpening, I’ll use P120, P320 and P800-grit sandpaper glued to a perfectly flat piece of granite. I could also use thick glass.

Now I can reassemble them to check whether there is a noticeable improvement. I put the springs in their holes, and attach the knives and tightening gibs. I’ll use these HPL parts I made to adjust the height. I screw them onto the holes that these machines have for the vacuum system when planing.

The springs will push the knives upward until they touch the two pieces I attached to the machine, and we must tighten the nuts when the knive is at the same height as the work table. If all goes well, we should be able to turn the drum without any problems.

I do some tests with the piece of chestnut wood and they definitely cut much better. See you soon!