Lately I’ve been receiving a lot of messages from users asking me what power tools are best for mounting on my homemade woodworking designs and machines, which can be found on this website.

So finally I’ve decided to write this article to try clear this up and answer all of your questions when purchasing DIY power tools or when mounting them on homemade machines.

Power tools for homemade woodworking machines

In principle, any circular saw, router, or jig saw can be used to make and be mounted on your homemade table saw or DIY router table, but there are some considerations which I’ll explain below.

The building process will be faster and more precise if you use a good set of handheld power tools to make your homemade woodworking tools.

Your homemade woodworking tools will be more precise, powerful and versatile if you mount good and appropriate handheld power tools on them.

For example, if you use a powerful handheld circular saw with discs of a large diameter, you’ll have a more powerful tool, with greater cutting height than if you were to use a small, cheap circular saw.

Also, if your circular saw, jig saw or router are good quality, you’ll be able to cut and mill more accurately. This happens because these tools tend to vibrate less than their cheaper counterparts, which also means they’ll help you work more comfortably.

Besides, these tools can be used for longer periods than cheaper ones because they use better components, such as bearings or electrical parts, in their construction.

Keep in mind the circular saw and jig saw have not been designed for inverted use, so they’ll suffer more wear and tear.

Another point to keep in mind is that if you use handheld power tools other than the ones I’ve used to make my homemade woodworking machines, you’ll likely have to modify the original design a little.

At the very least, you’ll most likely have to modify and resize the recess to attach the circular saw or the jig saw base.

As you might have deduced from my words, I’m partial to buying good quality power tools. You don’t need the best, most expensive ones or buy them all at once, but you do need something decent.

You’ll have tools that will last a lifetime if you use them correctly, and you’ll be able to operate them by hand or mount them on your homemade tools. You can also consider buying secondhand good quality tools, which I have done several times.

Corded or cordless power tools?

That’s been the million-dollar question in recent years. I’ll answer this briefly. If you’re not going to mount your power tools on your homemade woodworking machines, I suggest buying cordless tools. They’re perfect when you’re moving around the shop or your home.

If you’re planning on coupling them to homemade tools such as a table saw or a router bed and you’re not going to use them as handhelds too often, plain corded tools will be more comfortable to use.

In general, stationary machines such as table saws will do a lot more work than handheld tools, so this way you won’t have to change their batteries regularly.

Besides, you’ll be able to install and use an emergency switch, which is more complicated with cordless tools.

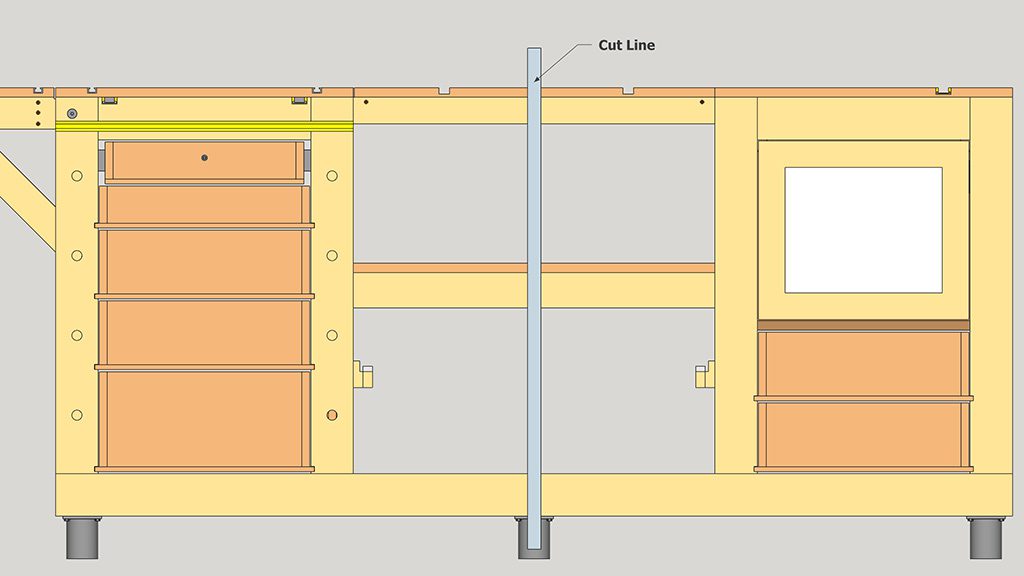

Circular saw for the Portable Workshop and Table Saw

With all that in mind, I’ll give you my final conclusions. Note that this information is only for orientation purposes, in general you should be able to use almost any kind of power tool.

As a handheld circular saw to use inverted on a homemade table saw, try to install a corded one, between 1200 and 2000W. Try to find one that can support at disc at least 210 or 235mm in diameter.

It would also help if the base is rather robust so that it can be firmly fastened underneath the top of the table. Some bases come with threaded holes for this purpose. If it’s not the case, you can drill and thread the base at home using screws and nuts.

Another point to take into account, the bigger the circular saw, the heavier its motor will be. That weight can tilt the disc toward the side of the motor, especially in a low position. I explained this in more depth in this article.

Verify this by placing a square on the table and touching the disc once installed. With my Makita 5903R you can barely notice it. It has a robust height locking system.

It’s extremely important that it has a riving knife. If it doesn’t, you’ll have to install one; either on the circular saw itself, or screwed to the top of the worktable. In this article you’ll find more information about table saw safety.

Router for the Portable Workshop and Table Saw

Try to install a 700-1000W router. Looking back, I could have made it without the router tilting system—I’ve barely used this feature.

I would buy a router plate insert for the machine’s worktable and screw in the router directly underneath. You can also fasten the fixed support that comes with the router to the underside of the table.

I also wouldn’t use the router with a 43mm spindle mount that I used. The Kress 1050 is extremely high quality, but it doesn’t have any accessories for handheld use.

My choice nowadays would be a Makita RT0700. I think it’s an incredible router—comfortable, powerful and very versatile thanks to all the accessories on the market, such as a fixed base and a plunge base.

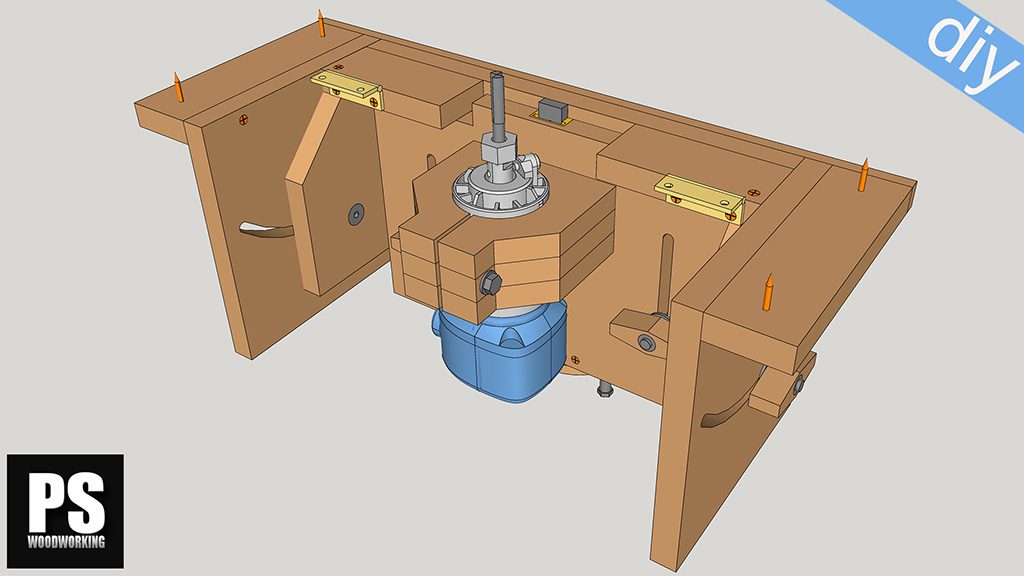

In the above picture you can see examples of the routers used by the readers of this website. You’ll find many more in this article.

The fixed base would be perfect for the underside of the table, so that we can take advantage of its height adjuster for router bits.

It’s also possible to install a larger router with a built-in plunge base, like the one you can see in the second photo. In this case, you’ll have to use the plunge base to adjust the height of your router bits.

Be careful when using the Portable Workshop. The cover on the router’s side may not close all the way when installing a larger router. I don’t think you’ll have any trouble with a router of the same type and size as a Makita RT0700.

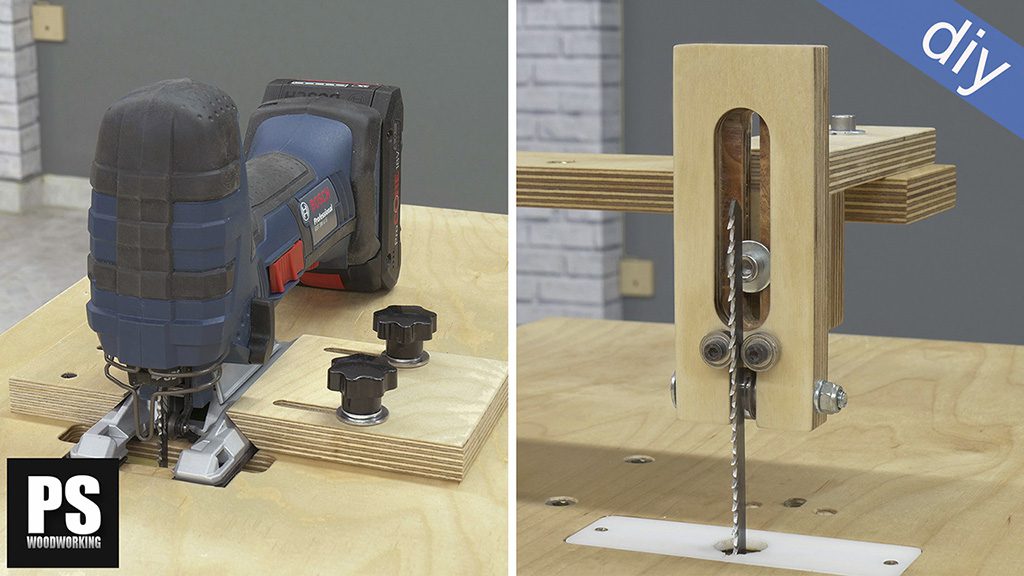

Jig saw for the Portable Workshop and Table Saw

Choosing a jig saw won’t pose as many problems. The only three considerations are that the base is good and robust so that it can be coupled to the underside of the table of the homemade tool, that it has RPM control so that you can adjust the speed depending on the materials, and, above all, that it is equipped with a quick release blade system.

Choosing a router for the 3D Router

This is not too dissimilar from the previous cases. If you’re planning on fixing your router to the 3D router, a Kress or one with a 43mm spindle mount would be perfect.

If you want to decouple the router to use it as a handheld, I recommend you install a Makita RT0700-style router, at least 500w. Also, you’ll find lots of spindle mounts on the market for these kinds of routers.

I used a 43mm spindle for my router so that I could also attach my drill, but I would advise against drilling too many holes in these kinds of homemade tools with bearings. Ideally you should use a column drill stand.

In the above picture you can see examples of routers submitted by this website’s users to mount in the 3D router. You can see many more in this article.

the portable workshop is amazing! do you have the plans?

thanks Matt, here you’ll find the plans:

hello, nice article! where can I find a 43mm clamping collar for my router?

hello David, check this out: